Here’s a few drawings showing typical wood construction details from my plans. Wood boats are still perfectly valid, and while they suffer from poor resale value and can be harder to sell than steel or plastic, they have a lot of good points. This isn’t worth discussing and certainly not worth arguing about; it’s strictly emotional and you either feel that way or not! I will say one thing though. Owning a wood boat gains you entry into the wooden boat festivals and THAT is always great fun….!

I spec out normal “traditional” wood construction with a bit of a twist. I’m also a home wood boatbuilder, and as a result I draw construction plans that I can build, and spec materials I can afford. This is nothing particularly original; I got most of my ideas from reading Bill Garden, Will Atkin, Sam Rabhl, Howard Chapelle, and various articles in old and now gone boat mags. Then I added a bit of 80s “immediacy” and I’ve been told “counter-culture” attitudes, and the results are pretty feasible building projects if I do say so! You hear a bit of flack about this attitude from some of the “purists” out there in the mists because they think that such an attitude is somehow suspect; it’s “do-able”to use a bit of today’s jargon, and to be faced with the idea that yes, an amateur can indeed build a large boat of wood, without a great deal of tools or money, annoys them because, I suspect, it means they can’t think of a good reason why they still don’t do it…… Talk is so cheap. I want to hear what people are DOING, not gonna do!

Forgive me; I enjoy poking fun at people who take things to seriously and believe me, many people, especially the younger ones who really don’t know what they’re talking about, have some strong strong opinions regarding what is RIGHT and WRONG about wood construction. I suspect I had a touch of that once myself but it disappeared many years ago when I realized if I was ever going to be able to build my own larger boat I had to get off my pulpit and spend some time around workboat builders to see how they did it. And you know, I found I not only came to understand the concept of simplicity, but, I came to appreciate and value it. A toy for a little Princes on a pond is one thing but a cruising boat is quite another! Anyway, for more than you care to learn about homebuilding a wood cruising boat read my BUEHLER’S BACKYARD BOATBUILDING available from me or in better bookstores everywhere. Now, here’s a few drawings.

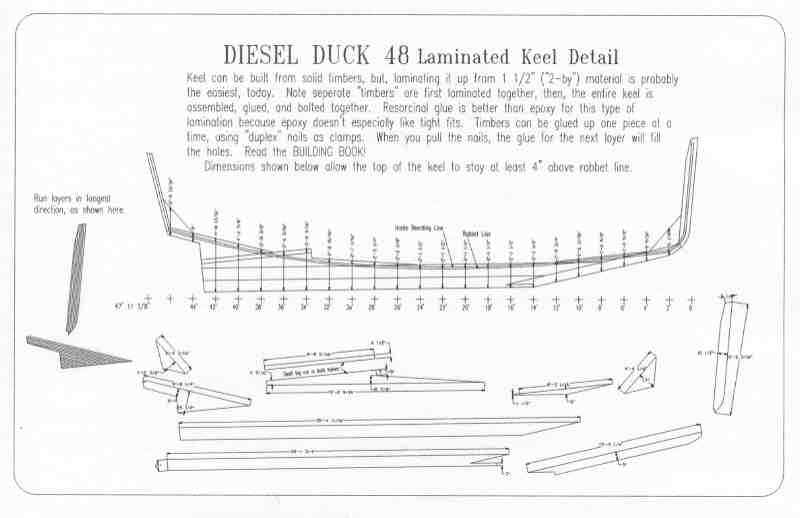

The keel is the “backbone” of the ship. Big timbers are expensive and hard to most places these days (we shipped much of our decent wood to Japan in the 1990s by the forest load) but “2-by” is still available in lumberyards. I spec out keels laminated into “timbers”from normal lumberyard house construction 2-bys.

The keel is the “backbone” of the ship. Big timbers are expensive and hard to most places these days (we shipped much of our decent wood to Japan in the 1990s by the forest load) but “2-by” is still available in lumberyards. I spec out keels laminated into “timbers”from normal lumberyard house construction 2-bys.

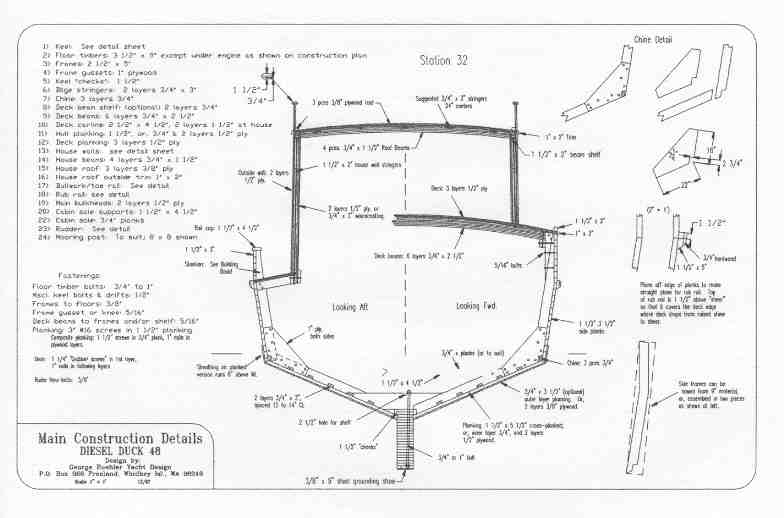

This is a construction cross-section that shows specific details at a “cutaway.” It’s showing two views, actually; on the left is the house and side deck, and on the right is a full deck beam and raised sheer. The 48 DUCK has both! To keep things simple I spec lots of lamination, making a single large piece from multiple layers of thin stock. You’ll note this is a “single chine” hull, a type of hull that is ideal for homebuilding both steel and wood. The wood version has frames that are two straight pieces joined at the chine by plywood gussets. It’s sort of like a house roof joist. The ones shown here are 2 1/2″ x 5″ frame pieces joined by 1″plywood gussets on each side, and makes a very very strong hull.A good table saw is essential. I’ve done it with a Sears Craftsman more times than I care to think about but now I own a $900 220volt Grizzly. The Craftsman works just fine but the heavier saw is easier. Good tools are always a big help…..

This is a construction cross-section that shows specific details at a “cutaway.” It’s showing two views, actually; on the left is the house and side deck, and on the right is a full deck beam and raised sheer. The 48 DUCK has both! To keep things simple I spec lots of lamination, making a single large piece from multiple layers of thin stock. You’ll note this is a “single chine” hull, a type of hull that is ideal for homebuilding both steel and wood. The wood version has frames that are two straight pieces joined at the chine by plywood gussets. It’s sort of like a house roof joist. The ones shown here are 2 1/2″ x 5″ frame pieces joined by 1″plywood gussets on each side, and makes a very very strong hull.A good table saw is essential. I’ve done it with a Sears Craftsman more times than I care to think about but now I own a $900 220volt Grizzly. The Craftsman works just fine but the heavier saw is easier. Good tools are always a big help…..

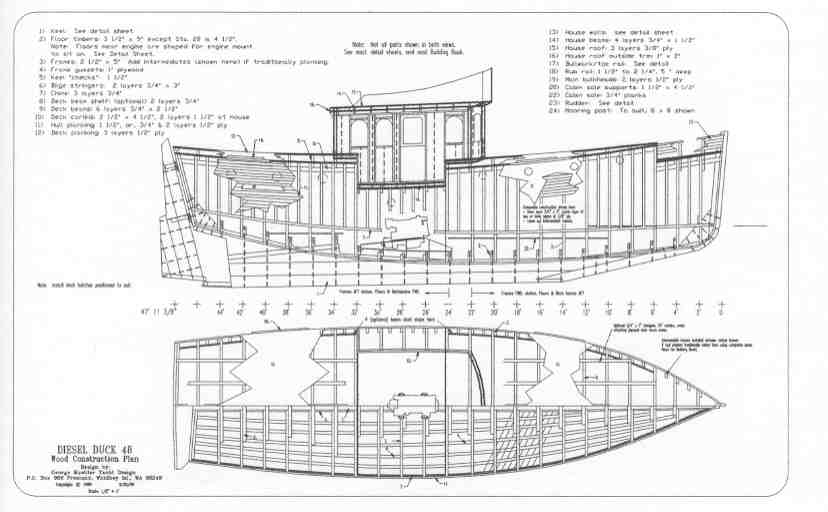

Here’s a typical Main Construction Plan. It shows just about every piece of wood in the boat. It’s hard to see in this drawing but if you look close you’ll see arrows with numbers above them pointing at various places, and then up above, is the written description. The bottom view splits the hull into two sections; the top is looking down on her from above the deck. It shows the deck frame and part of the deck itself.The lower half is the view from below the deck beams. you’ll note diagonal lines on this view just fwd. of the mid-section. There’s showing the first layer of planking which is installed on a diagonal.This is called “cross planking” or “planking ala Maryland,” is as old as time, and is very very simple. There’s little waste and easy fitting. Bigger hulls like this boat (48DUCK) will then have three layers of 3/8″ ply over the hull.Smaller ones like the 38 can get by with a single layer of “2-by”(1 1/2”) planking and no plywood. Or of course can be composite too.

Here’s a typical Main Construction Plan. It shows just about every piece of wood in the boat. It’s hard to see in this drawing but if you look close you’ll see arrows with numbers above them pointing at various places, and then up above, is the written description. The bottom view splits the hull into two sections; the top is looking down on her from above the deck. It shows the deck frame and part of the deck itself.The lower half is the view from below the deck beams. you’ll note diagonal lines on this view just fwd. of the mid-section. There’s showing the first layer of planking which is installed on a diagonal.This is called “cross planking” or “planking ala Maryland,” is as old as time, and is very very simple. There’s little waste and easy fitting. Bigger hulls like this boat (48DUCK) will then have three layers of 3/8″ ply over the hull.Smaller ones like the 38 can get by with a single layer of “2-by”(1 1/2”) planking and no plywood. Or of course can be composite too.

If you’d like to see some photos of a 48 DUCK being built of wood by a homebuilder, click Wood Photos!